We’re always here to help you

On the ground

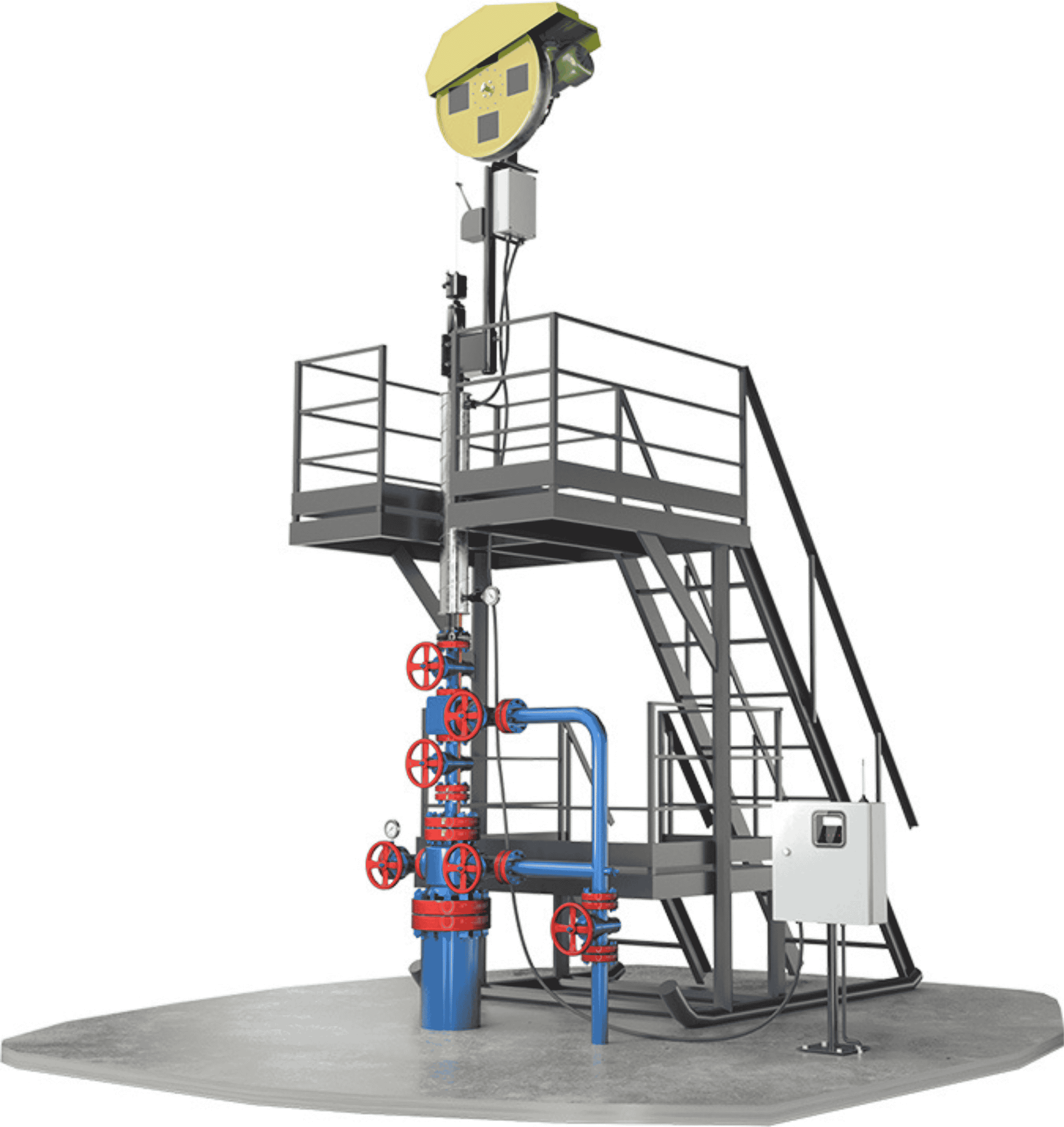

SA-30/40 Series Automated Dewaxing Unit

Intended use:

SA-30(40) can be used for geophysical logging with the help of a self-contained logging tool.

SA-30(40) can be operated either in manual (semi-automatic) or in automatic mode.

01

SA-30

02

SA-40

24/7 Support

Technical specifications

| Specification | SA-30 | SA-40 |

| Diameter of pipes to be cleaned | 60, 73, 89 | 60, 73, 89 |

| Operating depth to | 3,000 m | 4,000 m |

| Treatment speed (linear scraper travel speed) | Constant linear. Smooth adjustment from 3 to 17 m/min | Constant linear. Smooth adjustment from 3 to 17 m/min |

| Operating wireline diameter | 1.8–3.0 mm | 1.8–3.0 mm |

| Rate of frequency | 8 times a day to once a month | 8 times a day to once a month |

| Lubricator heating | Yes | Yes |

| Telemetry system connection | RS-485/MODBUS RTU | RS-485/MODBUS RTU |

Technical specifications

1. SA-30/40 Units enable the Customer to equip the entire well stock with the most suitable dewaxing mechanisms produced by Debit-E LLC.

2. Special automation settings and design solutions allow the SA-30/40 to show stable performance both on wells

equipped with an ESP and on flowing, periodic and gas lift wells

3. SA-30/40 has a very wide range of controlled parameters and settings, which allows the Customer to improve the cleaning process and achieve maximum economic effect.

4. SA-30/40 is firstly intended for automation of the process of mechanical tubing cleaning from asphaltene, resin and paraffin deposits with the trouble interval of more than 2,000 m.

5. SA-30/40 makes it possible for the Customer’s specialists to conduct a controllable dewaxing process with high speed in semi-automatic and manual modes.

6. SA-30 allows for both forced and free lowering of scrapers.

7. SA-30/40 system can be equipped with logging tools

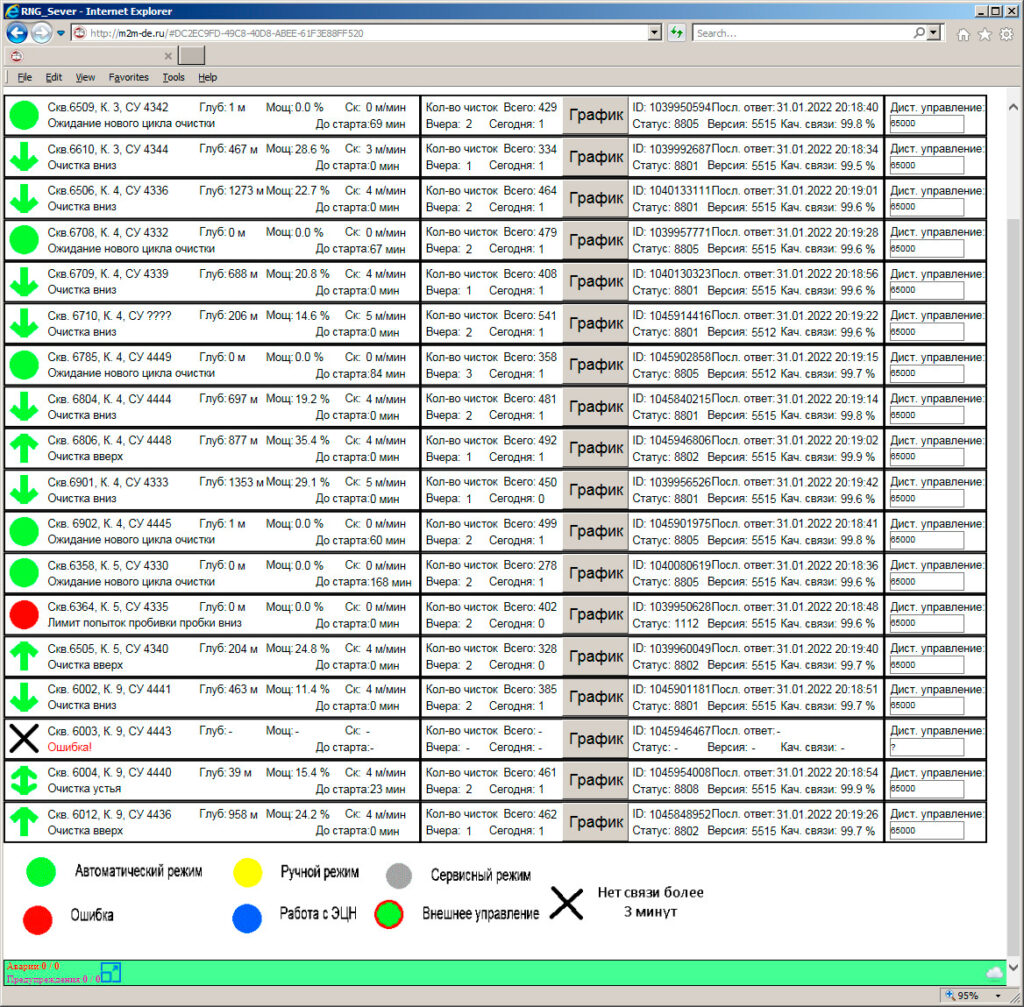

System for monitoring and control via the Internet

All MDSA winches are designed to be connected to the Customer’s telemetry system and to Debit-E Express Telemetry system via a free RS-485 port over MODBUS RTU.

Express Telemetry system by CTD:

Allows for monitoring the winch operation in near real-time mode:

– Allows for viewing summary information about all connected winches (status, depth, power, speed, communication quality etc.) on 1 page:

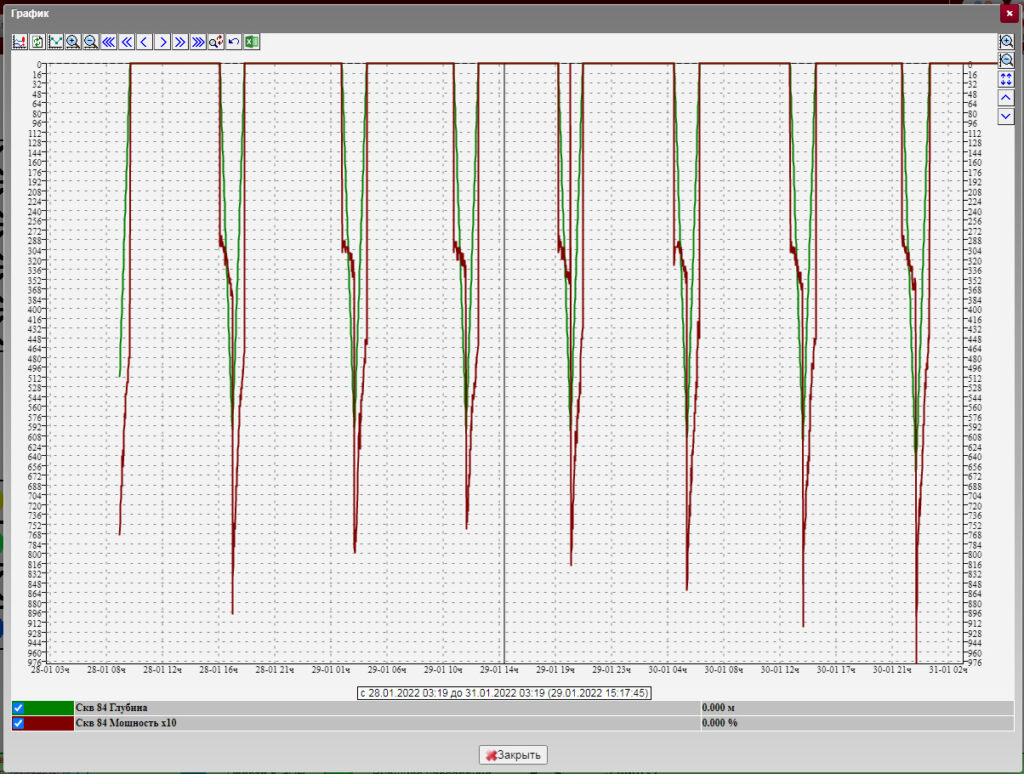

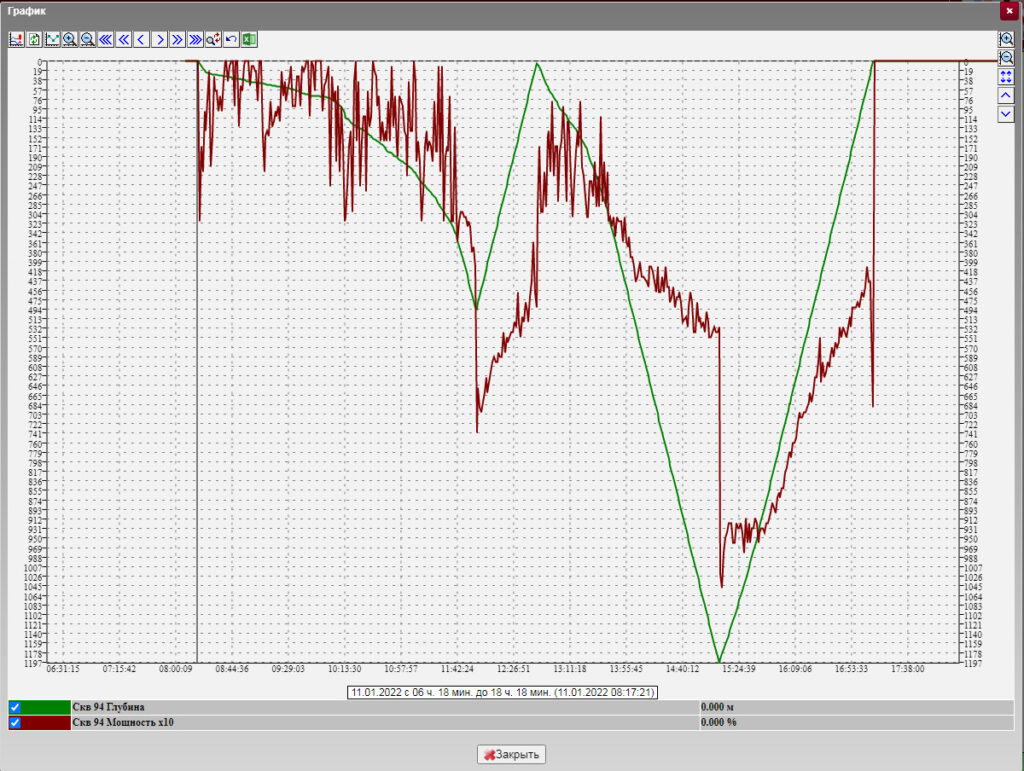

Winch operation graph

Allows for obtaining winch operation graphs for an arbitrary time interval;

– Allows for sending text messages about the winch operation process to specified telephone numbers:

Allows for remote SA Unit control: lifting and locking in the lubricator before the service team arrives, unscheduled startup of a cleaning cycle, lifting from error state, etc.

– Allows for monitoring and control from any device connected to the Internet (computers, tablets, or smartphones) without installing additional software:

Summary for the entire stock

Allows for remote changing of setpoints.

Allows for differentiating access rights in the Personal Account:

– Allows for connecting non-standard functions (operator presence control, text message about cabinet opening, sensor polling, and other telemetry data transmission, etc.).